How we Repair Loose or Broken Chair Parts

All types of wooden

furniture have

their own individual structural problems. Here is how we

replace loose

and broken chair parts;

Loose Joints

Seat frames are held by mortise-and-tenon joints (a prong or tongue or wood secured in a hole in the joining piece) or doweled joints (pegs of wood hold the pieces together) supported by triangular glue blocks notched to fit the legs. If we catch a loose joint in time, we repair it with glue. If the joint is broken, we have to disassemble it and replace the dowels. The triangular glue blocks will probably be glued and screwed to the frame, and the dowel joint might even be supported with hidden nail or screw fasteners. We separate the joint carefully, then replace the dowels. Making sure the joint is clean and dry before we reassemble it.

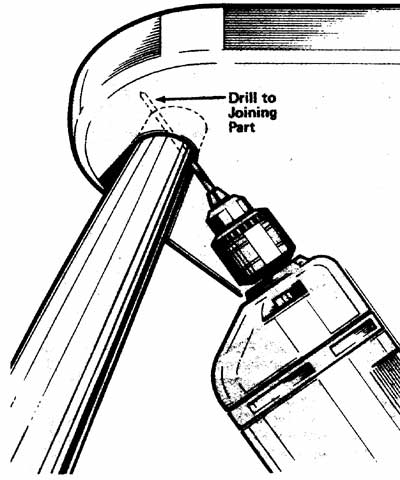

The metal angle is fastened to one side of the chair frame; the screw holes are predrilled and a piece of thin cardboard inserted under the opposite part of the angle, then the screw holes are drilled for that side. Screws are driven in fairly tightly, the cardboard removed, and the screws tightened up. When the screws are final-tightened, the angle will pull the joint tightly together to bridge the gap left by the cardboard.

Loose Legs, Rungs, and Spindles

Loose legs, rungs, and spindles can sometimes become loose on wooden chairs that are used excessively. But those problems can often be repaired.

Loose rungs or spindles -- and, where no bracing is used, loose legs -- can sometimes be mended by forcing glue into the joints. But a part mended this way may work loose again. For a more permanent repair, the part should be carefully separated from the frame. If both ends are loose, the entire piece is removed.

The old adhesive is completely removed from the part and from its socket. Glue does not bond well to old glue. Care is taken not to remove any wood from the end of the part or it won't fit right. After removing the old glue, each end of the part is tested in its socket. If the ends fit snugly, glue is applied to the socket and the loose part reinserted. The reglued joint is clamped, and allowed to dry completely.

If the part is loose in its socket, it will have to be enlarged to make a firm joint. If the tenon end is cracked, it will have to be reinforced. A thin coat of glue is applied to the tenon and it is wrapped tightly with silk thread. If necessary, more glue is applied and the tenon covered with another layer of thread. The threaded tenon is left to dry for a day, and then the reinforced end glued firmly into the socket. It is inserted carefully so as not to disturb the thread. The joint is clamped and allowed to dry completely.

Very loose legs or rungs can be wedged to fit if the tenon is sound. The part is clamped in a vise, then the center of the tenon end very carefully sawed into . The cut must be square and centered, roughly the depth of the part that fits into the socket -- about 2cm. For small parts, a hacksaw or a coping saw is used to make the cut; for thicker parts, a backsaw or combination saw is more suitable.

From a piece of soft wood -- pine quarter-round -- a thin wedge is cut to fit the width and depth of the saw cut in the tenon. The object here is to spread the saw cut slightly with the wedge, thus enlarging the tenon to fit the socket. When a wedge of the right size is made, it is very carefully tapped into the saw cut. When the tenon is slightly enlarged, any excess wood from the wedge is trimmed flush so that the face is smooth. Care is taken not to pound the wedge too far; excessive wedging will split the tenon.

To test the wedge, the end of it is inserted into the saw cut and tapped down. If the wood on both sides of the cut starts to spread, the wedge is too wide. Finally, glue is applied and the joint reassembled as above.

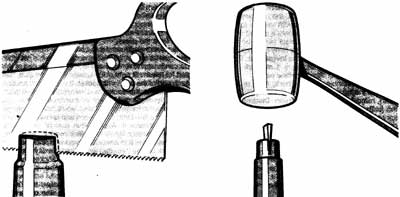

The piece of furniture may not be disassembled for this wedging procedure. In this case, there are two more ways to do the job. If the joint is extremely loose and appearance is not important, as much adhesive is removed as possible. Several thin wedges are made from molding -- pine lattice is a good material. The ends of the wedges are dipped in adhesive and the wedges driven with a hammer around the loose part between the part and the socket. Then, the ends of the wedges trimmed flush with the surrounding wood surface. The pressure from the wedges is equalized as they are driven in; unless placed carefully, the wedges can throw the part out of alignment, further weakening the joint.

Where appearance is more important, a 1.5mm hole is drilled through the side of the joint and the loose part. Then a metal pin is made from a 10d common or finishing nail. The head is cut off the nail with a hacksaw. A drop or two of glue is applied to the drilled hole, and the nail driven in. The pin is countersunk with a nail set or another 10d nail, and the hole filled with wood filler.

On chairs with horizontal rails across the back, the rails are mortised into the side posts; on chairs with vertical spindles or slats, these parts are mortised into a curved or straight top rail. Rails, spindles, and slats can all be replaced easily, but replacement may be fairly expensive -- if the chair isn't worth the investment, I wouldnt bother. If it is, a broken or missing part can be replaced with a new one can normally be costom made in our workshop.

First, the chair back is disassembled. It will probably be joined at the legs, seat, and rail. The joints are carefully pryed apart, any nails or screws being removed. Only the joints involved in the repair are disassembled. It usually isn't necessary to completely disassemble the piece to get at the part.

We can replicate the broken part, using a similar undamaged part from the same piece for reference. The old adhesive is carefully cleaned from the joints and the chair reassembled with the new part, gluing each joint. The chair is clamped with strap clamps until the adhesive dries, and then refinished completely.

Outdoor chairs made with wooden slats can be repaired the same way, but the slats can usually be replaced with wide moldings or thin boards. To replace a broken slat, we cut and shape a piece of wide molding or a board to fit the frame. If the slats are fastened with screws, we drill screw holes in the new slat and attach it with the old screws or matching new ones. If they're fastened with rivets, we drill the old rivets out and replace them with self-tapping or panhead sheet metal screws.

Broken Nonstructural Rungs and Spindles

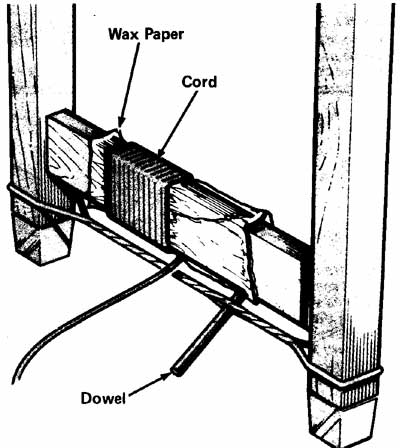

Splits and breaks in nonstructural rungs and spindles can be repaired with glue. We separate the broken ends of the part, and apply glue to each piece. If the part is only cracked, we force glue into the crack with a glue injector then join the pieces carefully, pressing them firmly together, and remove any excess glue. We wrap a piece of wax paper around the part, and then wrap the mended break firmly with a piece of cord to keep the part aligned properly. We clamp the chair firmly with a strap clamp or a rope, and let the glue dry completely.

Broken Arms, Legs, and Other Structural Parts

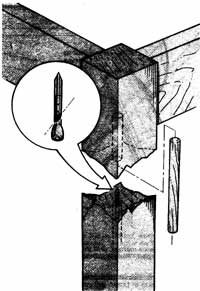

Where strength is important, the broken part must be reinforced. The best reinforcement is a dowel (wooden peg) pinning the broken pieces together. 3mm to 10mm dowel is used, depending on how thick the broken part is; dowel holes are drilled with a bit the same size.

The broken ends of the part are separated. In the center of one end and at a right angle to the break, a 25mm-deep-in hole is drilled, the same diameter as the dowel. This hole marks the dowel location. We cut off the head of a 16d nail, and insert the nail in the hole, point out. The point of the nail protruding only slightly above the broken surface. To mark the dowel location on the other piece of the broken part, we match the pieces and press them firmly together. The point of the nail leaving a tiny hole in the matching piece. We then drill straight into the second piece, about 25mm deep.

The dowel holes are measured, and a piece of dowel 6mm shorter than their total depth is cut to allow for glue buildup. The sides of the dowel are scored with pliers and the ends rounded slightly with sandpaper. This improves glue distribution and makes insertion easier. Glue is applied to one end of the dowel, and inserted into the hole in one end. Glue is then applied to the protruding dowel and to the face of the break, we then push the other piece of the broken part onto the dowel. The parts are matched perfectly,excess adhesive the part aligned properly. We clamp the chair firmly with a strap clamp or a rope, and let the glue dry completely., and the mended part is clamped as above.

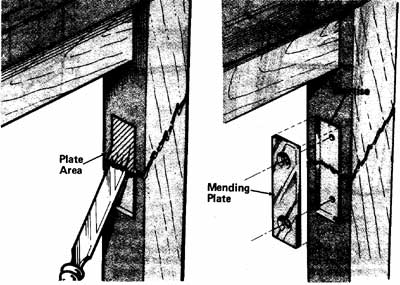

Where doweling isn't possible or where extra strength is required, we can use a steel mending plate to reinforce the break. Mending plates can be used on any flat surface.

The break is glues as above, and left to dry completely. Then a mending plate is added, long enough to span the break and narrow enough to be inconspicuous. A plate with screw holes beveled is used so as to accept flathead screws.

The mending plate is placed on the inside or least obvious face of the mended part. If appearance doesn't matter, it's possible to secure the plate directly over the break, using flathead brass screws. For a less conspicuous repair, we can mortise the plate into the wood. The outline of the mending plate is carefully traced onto the wood with a scratch awl or a sharp nail. We then score the wood along the outline with a series of straight-down chisel cuts as deep as needed for the mortise -- about 5 or 6mm for most plates. A little extra space is allowed to cover the plate with wood filler. The wood is cross-scored at right angles to the outline; the chisel then turned over, bevel side down, and the excess wood in the scored outline is removed, working with the grain of the wood and removing only a little wood at a time so as to result in a clean finish.

When the bottom of the mortise is as smooth and level as possible, the plate is tested for fit and any necessary adjustments made. Only when the plate fits exactly, pilot holes are drilled for the screws and the mortise is coated with a thin layer of glue. The screws are dipped in glue, the plate positioned in the mortise, and the screws driven firmly in. The glue is allowed to dry for several days, and the mending plate is then covered evenly with wood filler or a veneer patch. The texture of the filler is finished to match the wood.

The seat is the part of a chair that suffers the most wear and tear, which means it also is the most likely candidate for repairs. We'll cover various seat repairs in the next section.

LOCATION

LOCATION